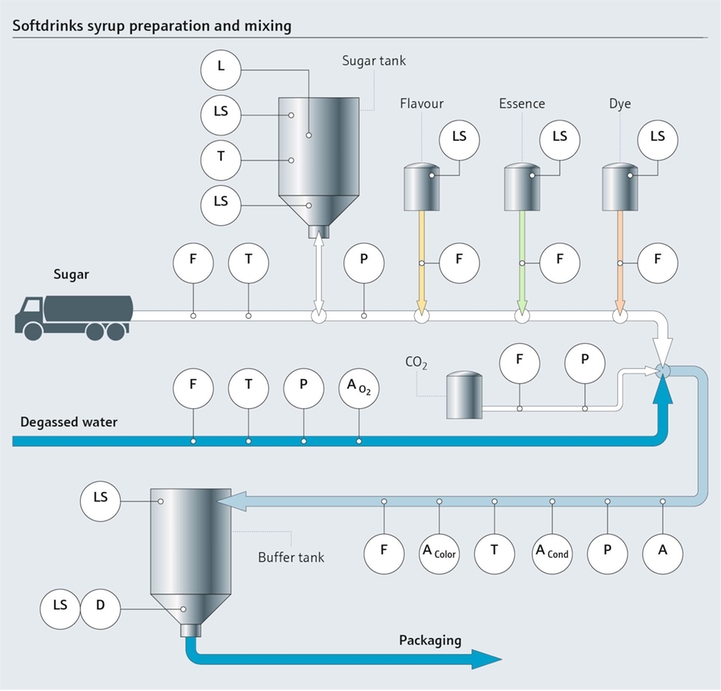

Ensuring consistent product quality is a top priority for the beverage industry. In this context, product safety, exact dosing of the raw materials, monitoring of all critical process parameters, complete data recording, but also cost awareness are important factors. Innovative process instrumentation helps to meet these challenges, from delivery and dosing of the raw materials to blending and filling of the beverages.

Key facts

130

billion litres

of soft drinks are consumed worldwide every year. Consistent product quality and the safety of the consumer are crucial. Source: www.historyofsoftdrinks.com

Application and process knowledge for soft drink production

Accurate sugar concentration

The sugar concentration is an important parameter for the consistent quality of a soft drink or juice. The concentration can be easily calculated by measuring the density or speed of sound. Inline measurement technology enables permanent quality monitoring based on real-time product data. This reduces time-consuming manual sampling and production downtime.

Our expertise in the field

Endress+Hauser offers various technologies for precise inline concentration measurement in soft drink production.

- Determine fluid density in pipes using Proline Promass Coriolis flowmeters, such as Promass Q.

- Discover real-time concentration measurement of liquids with Teqwave H. The device continuously measures the speed of sound and temperature, and delivers accurate concentration levels in different units such as °Brix thanks to predefined algorithms.

Dosing of additives

The correct conversion of the soft drink recipe depends on the precise dosing of ingredients and additives. On the one hand, this has a direct influence on product quality and, on the other hand, it also guarantees efficient handling of cost-intensive raw materials.

Our expertise in the field

Due to their low conductivity, it is necessary to use highly accurate flowmeters to dose additives, such as sweeteners, flavors or colors.

- Use Proline Promass F 100, the flowmeter with premium accuracy and an ultra-compact transmitter.

Reliable data management

The key to product traceability lies in seamless data recording. It enables targeted monitoring and optimization of your beverage production process.

Our expertise in the field

Using data managers from Endress+Hauser, the recorded process values are clearly displayed and stored. The data are secured by personal access rights with electronic signatures (in accordance with FDA 21 CFR part 11 requirements).

- Select the right data manager from a large portfolio depending on your specific process requirements and application.

Efficient phase separation

No more guessing: From now on, you know exactly what's in your pipes. Sensors for phase separation enable exact detection of the phase transitions between end products, discharge and cleaning media or the degree of contamination in the respective medium.

Our expertise in the field

Our optical sensors for precise inline color measurement in liquids detect even the slightest color changes. You can see whether and in what quality the product, cleaning agent or rinsing water are in the pipe.

- Use OUSAF22, an optical sensor for precise inline color measurement in liquids in the visible region of the electromagnetic spectrum.

Smart calibration management

Strict requirements and regulations in the food and beverage industry with regard to safety, quality and reliability make regular calibration a must. The focus is on measuring instruments that are integrated into a quality management system (e.g. ISO 9001, HACCP, IFS).

Our expertise in the field

Endress+Hauser's seamlessly traceable calibration - either on your premises or in our calibration laboratories - ensures long-term product quality, increases plant availability and increases the cost efficiency of your processes.

- Learn more about our corresponding services and and keep all your critical processes in spec.

Benefits

We put great emphasis on offering you the best possible solutions while guaranteeing consistent product quality and high process and product safety. Our experienced team of industry experts will help you select and design the right measuring instruments for your critical process parameters. We focus on sustainable customer relationships and want to be there for you in the long term.

Key facts

100%

product safety thanks to inline quality measurement

Key facts

30%

savings on consumables thanks to optical measurement technologies for phase separation

Key facts

>10%

of the global Endress+Hauser work force is service related

Our offering

Endress+Hauser understands the high demands and challenges faced by manufacturers of soft drinks. We offer a complete portfolio of hygienic flow, level, temperature, pressure and analytical sensors designed, manufactured and optimized for the food and beverage industry. Our common goal: increase, maintain and ensure product quality and consumer safety in the long term.

- Precise and reliable measurement technology optimized for the requirements of the beverage industry.

- Easy to clean and absolutely tight sensors. Ingress protection class up to IP69K available to withstand high pressure and steam cleaning.

- Hygienic sensors meet global sanitary standards and are certified according to EHEDG test procedure.

- Food contact material compliant to FDA "GRAS", EC 1935/2004 and China GB4806.

- Seamless integration into any control system.