Efficient business model with supplier-managed inventory

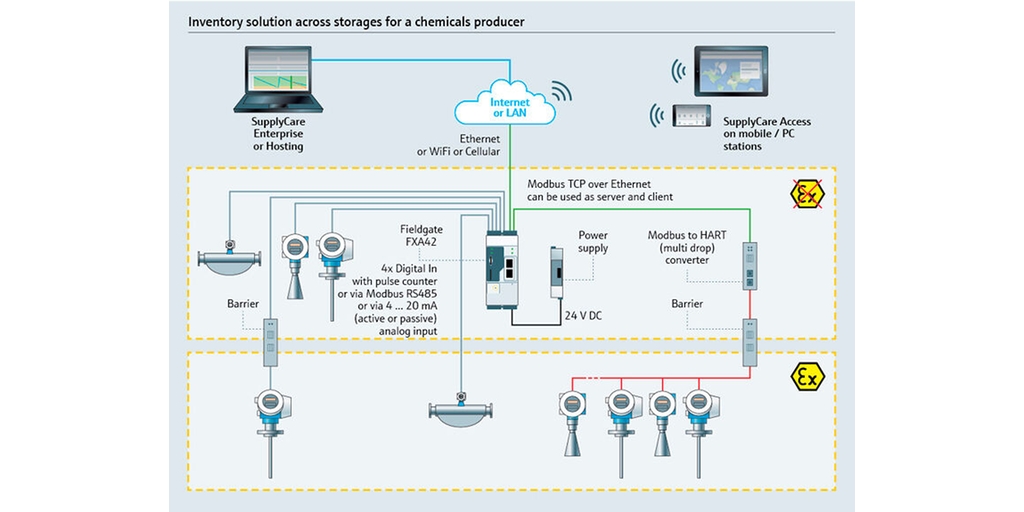

Inventory and supply chain solution across depots for a chemical producer

One new business model is the supplier managed inventory (SMI), where the chemical producer is responsible for the replenishment of

its stocks and delivery to its customers. It typically has from one to thirty tanks both for raw materials and final products distributed in one or

more production and distribution locations.

SupplyCare increases productivity

We measure continuously with our level devices. The data is sent automatically to SupplyCare – no need to climb up the tanks.

SupplyCare collects all the data and prepares it according to our customer's needs. He has full visibility, if a tank is full or low. Nno tank will be overfilled due to lack of information.

Report module of SupplyCare offers a flexible, easy configurable and comprehensive reporting integrating data from level, flow in, flow out comparing them to determine the yield

Inefficiency through manual work

Manual dipping, which is commonly used to determine the level in the tank, is expensive and dangerous for employees.

Our customer manually enters the tank levels in different systems. There is no overview over all the inventories.

Overfill via manual operation is quite common and dangerous

Our customer needs to have a daily report on the inventory.

A transparent overview of the quantities of product “in”, “used” and “out” of the facility is necessary to ensure zero loss in the company.

SupplyCare helps

SupplyCare collects all the data and prepares it according to our customer's needs.

Guided radar measurement Time-of-Flight Levelflex FMP5x

Radar measurement Time-of-Flight Micropilot FMR5x